Solution by Mergenthaler

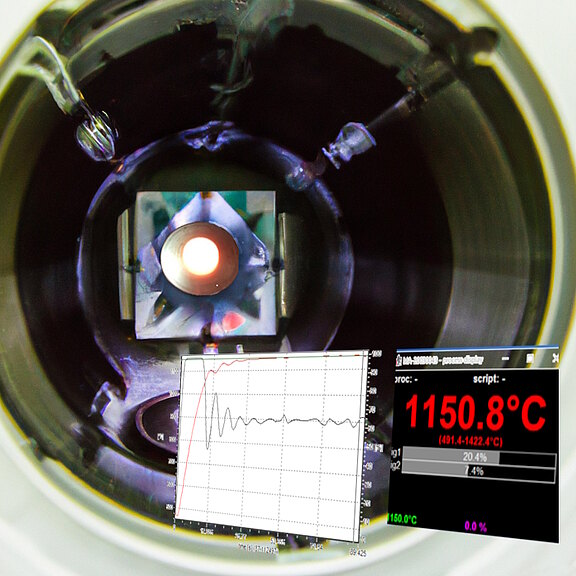

- Mergenthaler is a reputable supplier of components and systems for laser substrate heating based on unique diode laser systems. Mergenthaler laser processing heads provide reading of the target temperature by contactless, highspeed infrared pyrometer coaxial with the laser beam. Coaxial monitoring of the process by video camera surveillance is also included

We offer pyrometer temperature ranges from typical 100°C up to 2500°C in different spans with 10.000 temperature measurements per second. With the powerful LASCON Process Manager software, the user can program complex temperature curves to be performed precisely by the closed loop controller. It is also possible to create an own software GUI by using Mergenthaler TCP/IP command handbook, which fully supports your personal creativity

Especially for vacuum heating, the laser is an ideal solution:

No contamination of the vacuum by contactless heating and contactless temperature control - a Laser head outside the vacuum processes the target through a glass window

Higher heating rates and temperatures than conductive heating with virtually any temperature profile

Distance target to laser head up to 500mm

Variable spot geometries typically from 3x3mm up to 15x15mm

Special spot homogenization and shaping to transform the gausian laser beam into flat, homogeneous squares, rectangles, hexagons, octagons… for enhanced temperature homogeneity on the target