For decades, Mergenthaler has been a reputible supplier of laser systems and components for Laser Assisted Bonding.

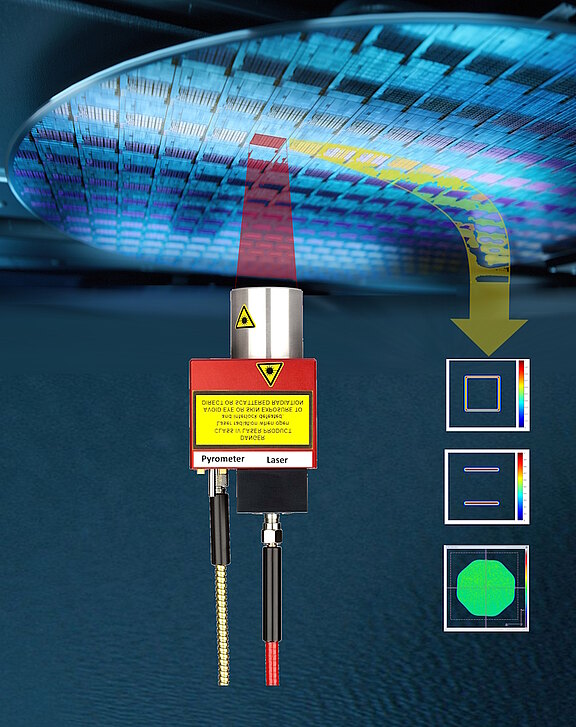

Laser Assisted Bonding benfits from the fact, that laser energy leads to a small, localized impact of heat to process small components individually. Fast heating rates under pyrometer control prevent oxidation of surfaces and lead to short production cycles of the individual components. Even with full assembled substrates, each component can be processed individually without affecting the neighbor components. Due to the low thermal impact, thermal elongation of the substrate is negligible and positioning accuracy of the components is enhanced.

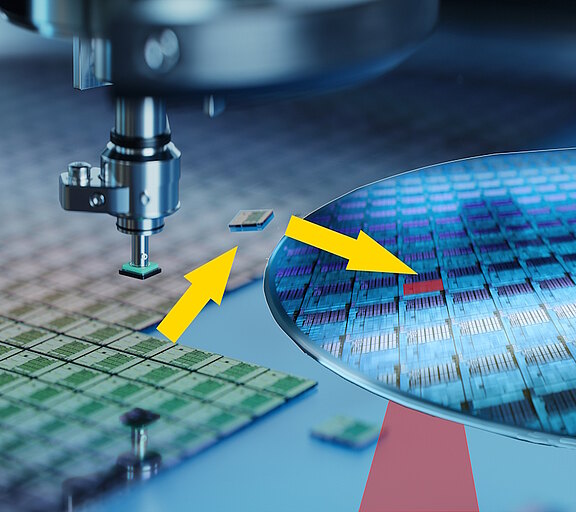

Well known packaging processes like chip on submount (CoS), chip to chip (CoC), chip on wafer (C2W) and others can be conducted by Laser Assisted Bonding.

Mergenthaler laser components have been used for packaging of photonic components like laser to fiber coupling, optical device packaging in general, die bonding, flip chip bonding or eutectic bonding (laser soldering). Even Laser Assisted Curing is possible.

Depending on the kind of substrate , the process can be done in two different ways. If the substrate is transmissive, the solder will be directly melted. If the substrate is absorbing, it will be heated at the bottom and the heat is conducted through the substrate to the solder.

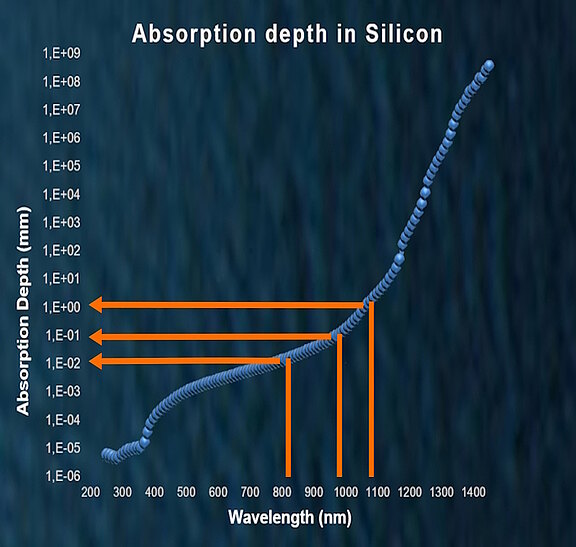

If the substrate is a silicon wafer, the absorption depends on the wavelength of the laser. By knowing the spectral transmission curve of the silicon wafer and choosing a proper laser wavelength, different effects can be achieved. The heat can be absorbed at the bottom surface or in the volume of the substrate or at the top of the substrate.

The diagram below shows the absorption depth of pure silicon as a function of wavelength.

For the laser wavelength 808nm, the absorption depth is about 0.01mm.

For the laser wavelength 975nmnm, the absorption depth is about 0.1mm.

For the laser wavelength 1064nm-1080nm, the absorption depth is about 1mm.

By absorption depth we mean the distance after which the laser power still has 37% of the initial intensity.

If the silicon wafers are doped, the absorption behavior may change and the spectral transmission should be measured.

If the substrate is metallized, a blue wavelength laser ( 450nm ) should be considered for heating.

Blue light is absorbed much better here than the light from the NIR diode lasers.

If the metallization consists of gold, the blue laser is the only reasonable alternative.

MERGENTHALER offers high brightness blue lasers with laser powers up to 100W in 200µm fiber - air cooled !

Discuss your ideas with our engineering team and benefit from more than 30 years of experience in laser technology.