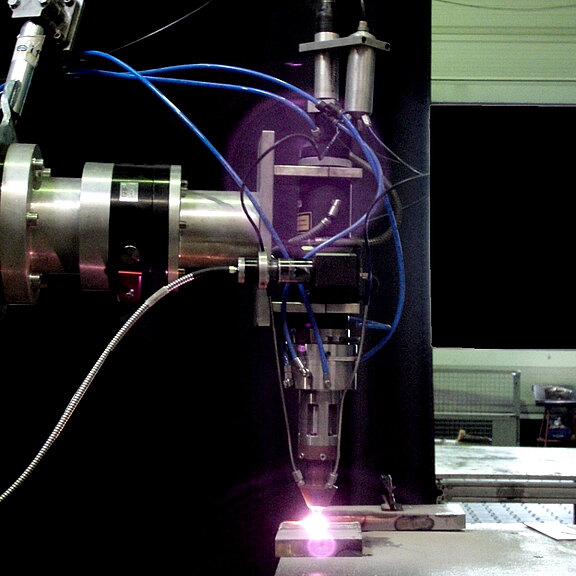

Solution by Mergenthaler

- Coaxial pyrometer measures the workpiece through the powder nozzle

- The heating of the component is compensated for by reducing the laser power with increasing process time

- The process temperature is regulated, monitored, saved and visualized

- The control is carried out by the LPC04 LASCON controller