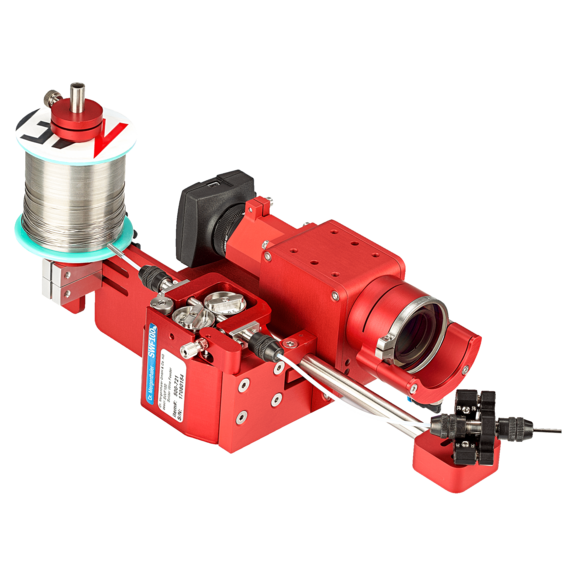

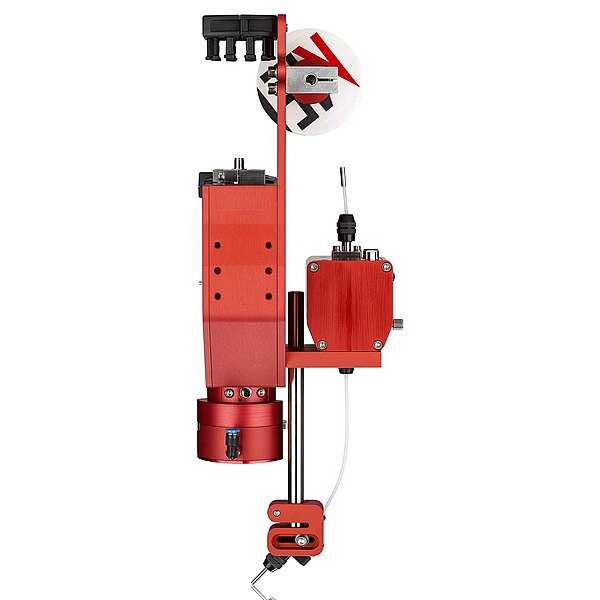

LH200 ZooOM

Adaptive Laser HeadThe LH200ZooOM laser processing head has a changeable spot diameter with constant working distance.

- Adaptive spot diameter

- Zoom factor up to 8 for laser and infrared pyrometer

- Smallest spot diameter 0.3mm

- Spot diameter adjustable by LASCON Process Manager Software

- Fixed camera picture

- Optional with solder wire feeder

Laser material processing like laser soldering of electronic components need sometimes the possibility of an adjustablelaser focus diameter. In case there are no other instruments like a camera or a solder wire feeder mounted on the laser processing head, this can be simply done by defocusing (changing the working distance). But if there is a wire feeder with the laser processing head, defocusing is not possible anymore.

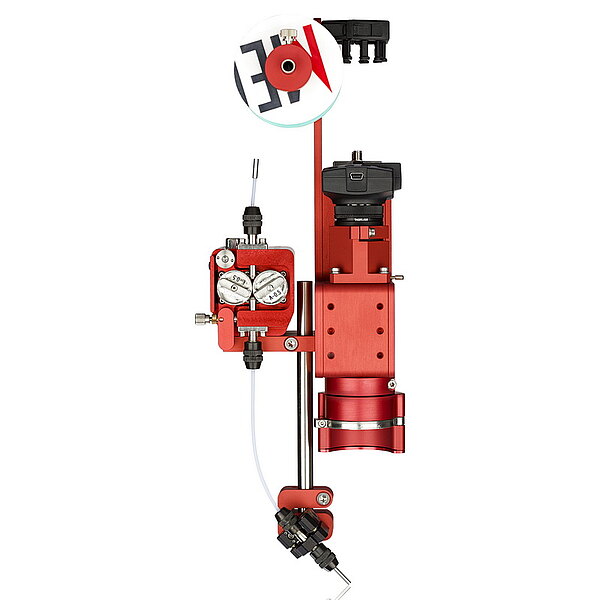

The LH200 ZooOM overcomes this problems and makes it possible to adjust the spot diameter in the range of 0.3mm to 2.5mm diameter. The value can simply be changed with the LASCON Process Manager Software. The optical pyrometer, which is reflected into the beam path of the laser, follows also the spot change. Therefore, pyrometer and laser are still completely coaxial. The CCD camera is not affected by the spot change and delivers always accurate and brilliant videos.

The fiber coupled infrared pyrometer is projected into the laser beam by a beam splitter. The pyrometer signal is digitalized inside the LASCON process controller witha resolution of 20 bits every 0.1ms . The infrared signal is send to the LASCON controller by a glas fiber cable. This set up guaranties highest protection against emi as all components inthe laser head are only optical. The laser head is capable of up to 140W laser power and we offer different glasfiber diameters and lengths.

- Optical Power: for fiber coupled lasers max. to 140 W

- Wavelenght: 808nm - 980nm

- Optics:AR coated 1.0“-optis, focal lenght on customers request

- Typical measuring range of the infrared pyrometer 140°C - 700°C, other measuring ranges up to 2500°C on request

- Acquisition Time: 100μs

- Software: LASCON® Process Manager, unique measurement and control software

- Hardware: LASCON® controller

- Usable fiber connector: FSMA905Fiber diameters:typical 100μm-600μmNum. Aperture:0.22, others on request

- Adaptive Laser Spot: with working distance 100mm approx. 0.3mm to 2.5mm

- Dimension of laser head: 50mm x 110mm footprint, height approx. 240mm (depending on the bending radius of the fiber )

- Protection: IP50Weight: 2.0 kg with mounted solder wire feeder, as shown above

- Pilot laser beam: Pilot laser, Laser Class 3R, Wavelenght 635nm Adjustable by LASCON® Laser Controller