LASCON Camera Manager

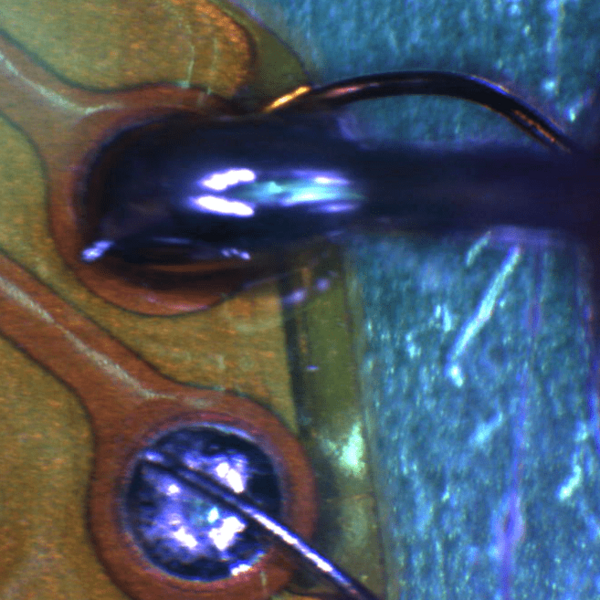

Storing and evaluating process videos during laser solderingThe LASCON Camera Manager is a camera and software system for optimizing laser processes using process videos

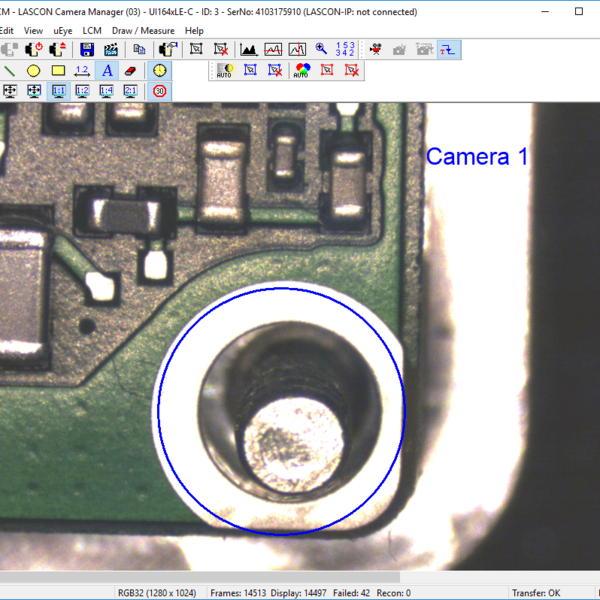

- Frame rate, brightness, contrast, image section of the camera freely adjustable

- Overlay for drawing in the laser spot and component geometries to check the component position

- Optional saving of all or individual processes in the event of process errors detected in the LASCON Camera Manager

- Scroll the process videos frame by frame

- Optimizing the timing of laser soldering

The LASCON® Camera Manager is a software package for saving videos and works in handshake to the LASCON® Process Manager.

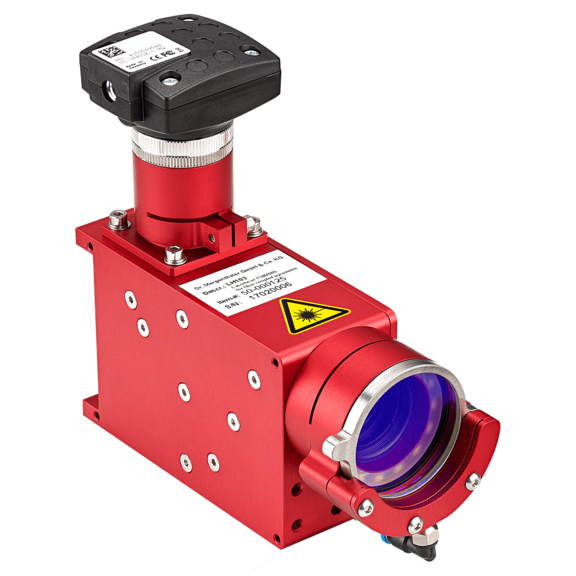

The optional integrated video camera in the laser head LH501 and LH103 is read out during the process and the video file is kept in memory. With the LASCON Process Manager, parameters and monitors can be defined in the script software. The laser process has to be executed within this limits. If the set limits are exceeded, the LASCON Process Manager generates an error signal. The Camera Manager can be configured to save a video file of the failed process to disk. The faulty process can then be analyzed image by image and the production optimized. As option, the Camera Manager can also store each laser processing video. This option can be used in the developement stage so that each process can be analyzed.

- Adjustable image size, frame rate, exposure, analog gain, color correction

- Image overlay for laser spot diameter

- Optional storage of all videos, only with Process error or never.

- LASCON Software Manager is triggered by the Process Manager via internal hand shake

For the LASCON Camera Manager you need a Windows PC with the current operating system.