Intelligent Laser Processing Head

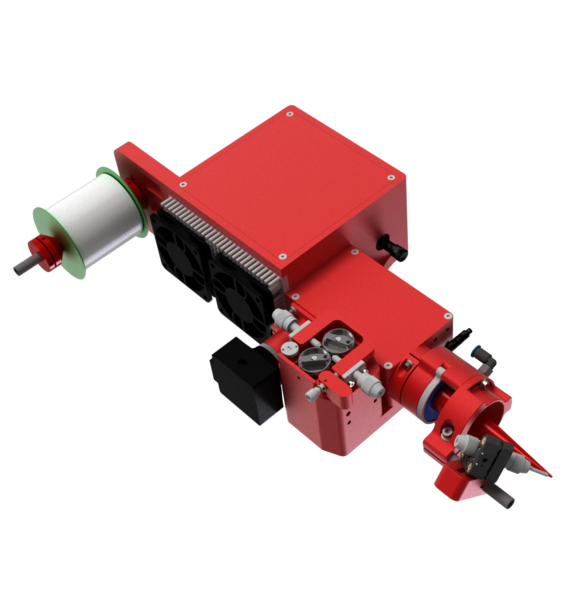

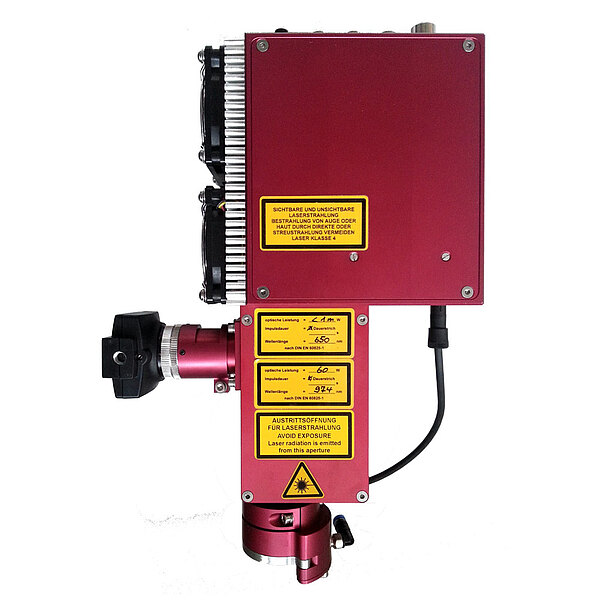

ILPH with integrated diode laser and LASCON ControllerThe ILPH laser process head is a direct diode laser with built in LASCON Closed Loop Process controller including pyrometer and camera, optional with wirefeeder and ring light source.

- 60W laser power

- Smallest spot diameter 0.2mm

- Integrated infrared pyrometer and process camera

- Infrared pyrometer and process camera coaxial with the laser beam

- 24V dc power supply

- Communication over Ethernet with LASCON Process Manager Software

Laser systems and laser processing heads can usually only be integrated by specialists in machines and systems. The handling of fiber optic cables is critical. The ILPH is a complete laser processing system including diode laser (60W), LASCON® process controller, pyrometer, camera, optional wire feed controller and ring light source - all on board.

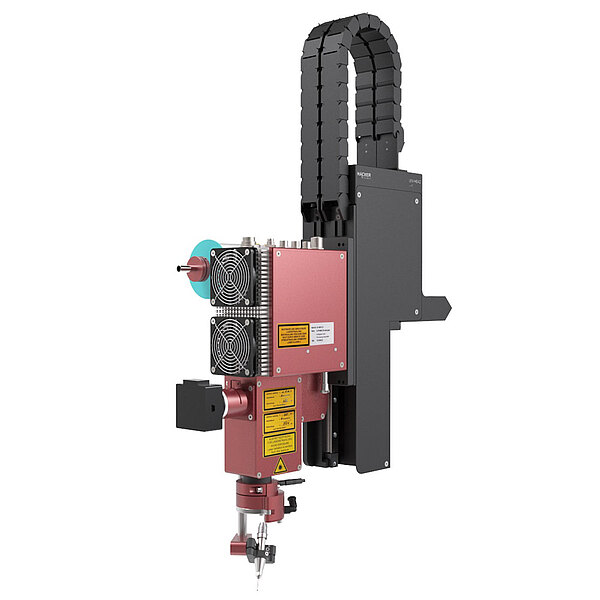

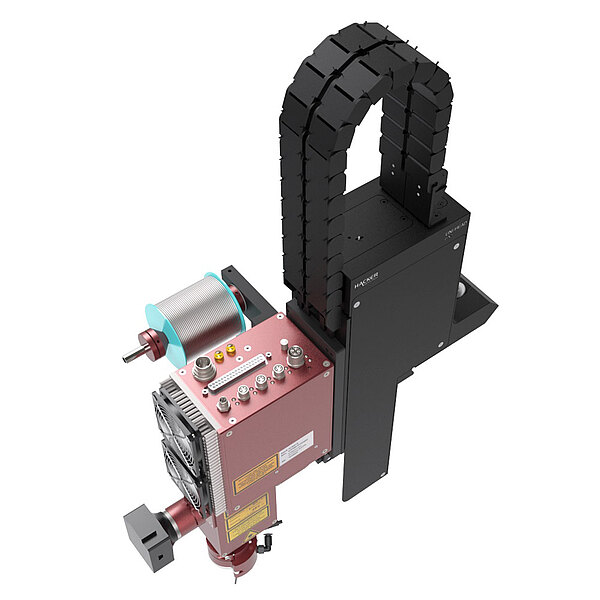

The ILPH can be mounted directly on a machine axis.

The ILPH requires only 2 cables: 24V dc and field bus Ethernet (optional EtherCAT)

- Laser power up to 60W

- Wavelength 978nm, others on request

- Laser spot diameter down to 200μm

- Easy to integrate in machines and plants via digital and analogue I / Os -> LASCON

- Easy to integrate with laser safety

- Bus connection: Ethernet or optional EtherCAT

- Integrated high-speed pyrometer with 10,000 measurements per second

- Temperature measuring range typically from 120 ° C, optionally from 70 ° C

- Integrated process controller for closed loop control with 10,000 control steps / s

- Software package for process control: LASCON Process Controller

- Software package for video camera: LASCON Camera Manager

- 256 programmable laser process scripts

- Data storage on internal flash disc

- Data export to the hard disk of a production server possible

- Power supply 24V, 8A max

The intelligent ILPH laser processing head is an ideal tool for integrating laser soldering into machines and systems.

All you need is the ILPH and a few cables (2,3). With these component you can go directly into laser soldering with pyrometer control. Thanks to the high brilliance, even extremely small laser spots up to a diameter of 100μm can be realized.

Other applications include laser plastic welding, laser heating and other laser processes.

The products presented here comply with laser class 4. The laser may only be operated in an environment that complies with national and international safety regulations.

Due to its compact design, the entire laser technical component is integrated in the process area. Therefore, it is relatively easy to build Category 1 laser equipment.