LASCON Process Manager

Measure - closed loop control - monitor and save in real timeThe LASCON Process Manager is a powerful software for measuring, cloesed loop control , monitoring, storing and visualizing process temperatures

- Over 1,700 installations worldwide

- On the market since 20 years - now 5th Generation

- Unique, adaptive controller with significantly improved behavior compared to the PID control algorithm

- Stand alone execution of all processes

- Software supports complete recalibration of the pyrometer after installation in laser heads

- Temperature measurement traceable to standards

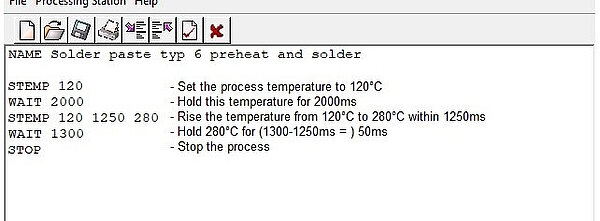

- Comfortable script editor allows the definition of complex laser processes

- Wire feed and ZoOOM ( LH200 ZoOOM ) function integrated in script commands

LASCON® is the process monitoring system with probably the largest distribution in the laser industry. More than 1500 users worldwide in industry and research monitor and regulate their laser processes with LASCON®.

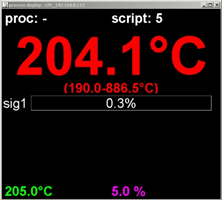

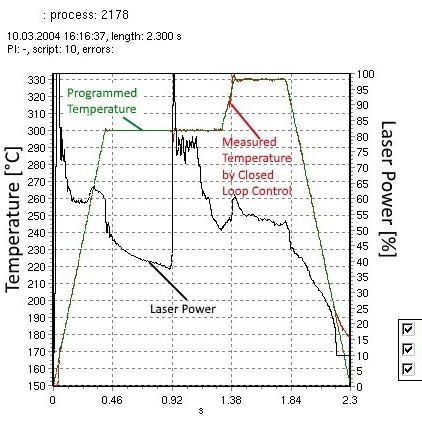

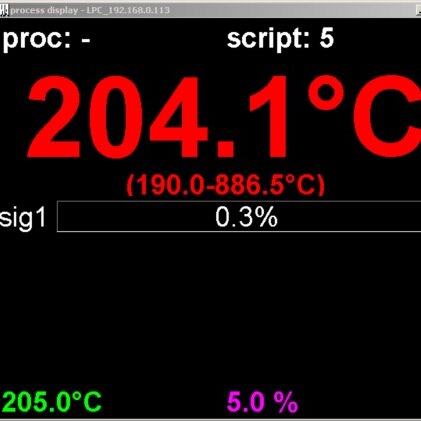

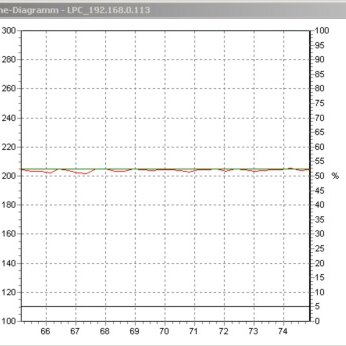

The LASCON Process Manager uses the infrared or 2 color pyrometers to measure the temperature on the workpiece 10,000 times per second and compares the measured temperature with a specified setpoint temperature. From the difference, the systems calculated the rated power for the laser system. This laser system is controlled by an analogue signal so that any laser system can be used with analog voltage power input. But it can also control inductors and other heat sources. The processes are monitored, stored and visualized. The process data of each process can additionally be exported automatically to an external server. Easily programmable scripts can be used to set monitors around setpoint temperatures to create an error signal if the measured temperature is not within the temperature monitor. Especially for laser soldering, the solder wire feeder can also be parameterized and started by software from the script.

- 100% process control - every part monitored and every process stored

- Monitor temperature and power

- Good / bad detection with output of error signal to PLC

- Write process scripts with simple programming language

- Store up to 255 process scripts and call (digital)

- Write up to 500,000 processes on integrated flash disk

- Self-diagnosis of the system

- Handshake to the LASCON® Camera Manager

- Measure the temperature 10,000 times per second with LASCON® and read and set all the I / O's of the LASCON® controller.

- Compare the actual temperature 10,000 times per second with the setpoint temperature and control the heating source (laser, inductor) . Real-time system with unique adaptive controller

- Check all set monitors in real time during the laser process

Applications:

Laser soldering, laser plastic welding, laser hardening, laser cladding, laser metal welding (also intermetallic compounds aluminum - steel, copper - aluminum), laser heaters for industry and research (for example in crystal research), induction hardening, induction brazing.

laser soldering

Laser plastic welding

laser hardening

Laser Cladding